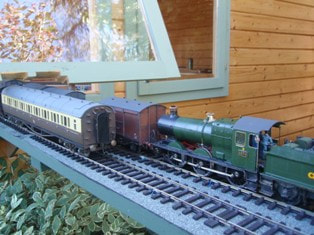

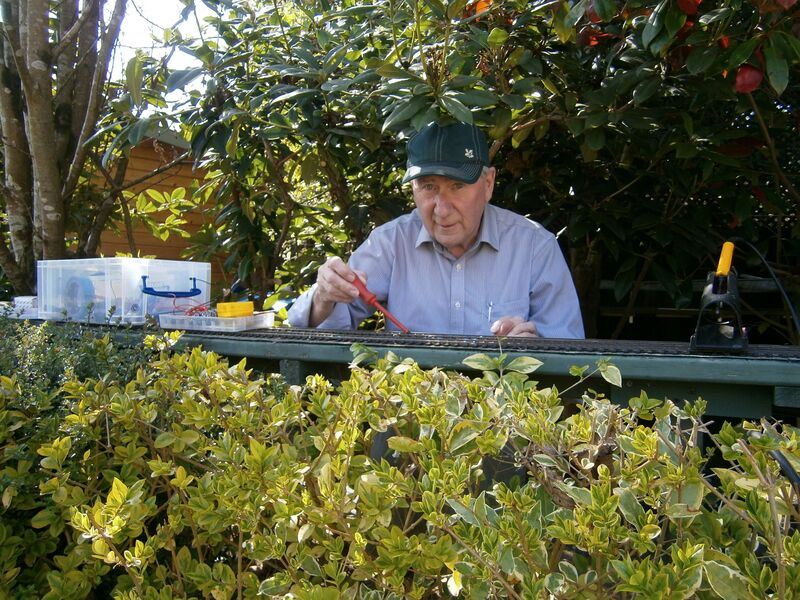

Paperclip (Indoor-Outdoor Layout by Keith. Great Western Railway in 7mm Scale

Keith's O Gauge layout is based on a Paperclip shape, with an internal complete circuit, then a loop running outside on an elevated section due to the ground slope at the property. His New Station building, The build shape might be of interest to those who do not have much room! Like the Great Central stations, the buildings are in two parts, with a variation of doors and windows. The complete building is 600 mm with a 60mm divide, I have made use of LCUT'S full range of products. Progress is being made. DCC operation with Lenz control.